1. Remove. For the hydraulic valve block, although most of its parts are connected by bolts, the hydraulic valve block is not disassembled when it is designed. If it is forcibly disassembled due to lack of equipment or technology, the result may be damage to the hydraulic valve. Therefore, before disassembly, the maintenance personnel should master the structure of the hydraulic valve block, and the connection mode between various parts, and record the position relationship between different parts in the disassembly process.

2. Check and clean. Check the valve body, valve core and other parts to observe the dirt deposition. On the basis of no damage to the working surface, use brush, cotton yarn and non-metallic scraper to remove the concentrated dirt.

3. Rough wash. The valve core and valve body are placed on the tray of the cleaning box, heated and soaked, compressed air is filled at the bottom of the cleaning tank, and the residual dirt is cleaned by using the stirring effect of bubbles. Ultrasonic cleaning is feasible if conditions permit.

4. Fine. Firstly, high pressure positioning cleaning was carried out with cleaning solution, and then hot air drying was carried out. If the enterprise has the conditions, it can choose the existing fresheners. In some different occasions, it can also use organic cleaning agents, such as gasoline and diesel.

5. Assembly. According to the schematic diagram of hydraulic valve block or the assembly relationship of parts recorded during disassembly, attention should be paid to the operation in the assembly process to prevent parts from being damaged. Hydraulic valve block processing for some of the original sealing materials, in the actual disassembly process is easy to be damaged, so in the assembly should be replaced.

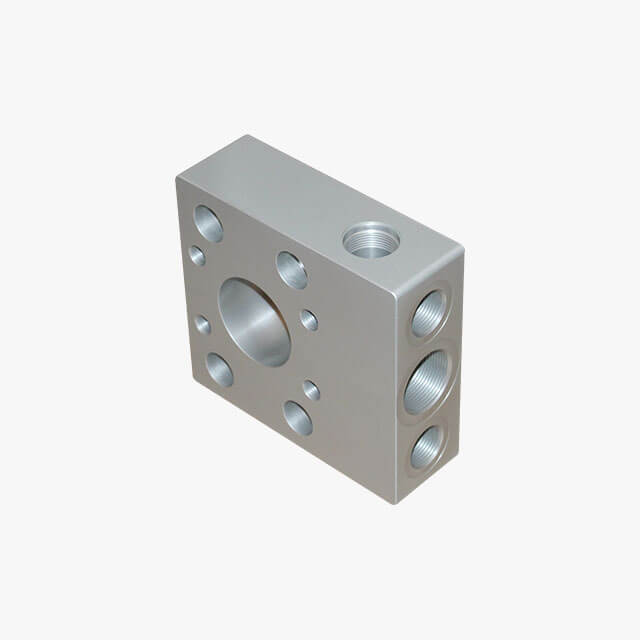

Valve manufacturers hydraulic manifold block design points, hydraulic manifold block design should pay attention to what points? The following is a brief introduction to the design points of the hydraulic manifold block: 1. The oil passage in the block should be as simple as possible, and the deep hole, inclined hole and process hole should be reduced as much as possible; 2. For the components with vertical or horizontal installation requirements, the integrated block should be designed according to the installation requirements; 3. Compact structure, small volume and light weight; 4. The components that need to be adjusted frequently (such as relief valve, speed control valve, etc.) should be installed at the position convenient for operation and observation; 5. A sufficient number of pressure measuring points shall be set on the block.