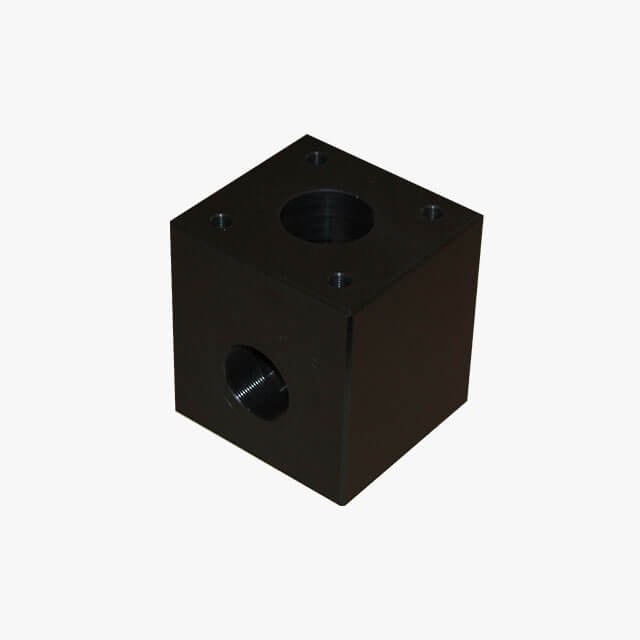

The hydraulic valve block processing system consists of hydraulic control unit, servo cylinder and power oil station. Now hydraulic valve block processing manufacturers - give you a brief introduction to the valve block composition.

The hydraulic control unit consists of speed control valve control unit and turbine stator blade control unit. Each unit is composed of electro-hydraulic servo valve, electric solenoid valve, quick closing solenoid valve, oil circuit block and base.

The servo cylinder is of double piston rod structure, with low friction and good sealing performance.

The power oil station is composed of oil tank, variable displacement oil pump, oil filter, cooler, pipeline valve, detector meter, etc.

The layout optimization principle of hydraulic valve block.

If the number of hydraulic components on one side of the hydraulic valve block is less than 4, the hydraulic components should be arranged around the four corners, not necessarily on the corners. In this way, the process holes can be designed near the two sides.

If the number of hydraulic components on a certain surface of the hydraulic valve block is less than 8, the other hydraulic components can be arranged near the four sides according to the situation, except that the hydraulic components are arranged near the four corners. In this way, the process hole can be designed near one or two sides.

If the number of hydraulic components on one side of the hydraulic valve block is more than 8, the valve block manufacturer can consider using intelligent method for optimization design.

Installation position of hydraulic valve block.

Upper vertical: the pump device is vertically installed on the cover plate of oil tank, mainly used for quantitative pump system.

Upper horizontal: the pump device is horizontally installed on the cover plate of oil tank, which is mainly used for variable displacement pump system to facilitate flow regulation.

Side mounted: the pump device is horizontally installed on a separate basis beside the oil tank. The side mounted pump can be equipped with a standby pump, which is mainly used in the system with a large oil tank capacity of 250 liters and a motor power of more than 7.5 kW.

Hydraulic valve requirements.

Flexible action, reliable function, small impact and vibration, low noise and long service life.

When the fluid passes through the hydraulic valve, the pressure loss is small; When the valve port is closed, it has good sealing performance, small internal leakage and no external leakage.

The controlled parameters (pressure or flow) are stable, and the variation is small under external interference.

Compact structure, easy installation, debugging, use and maintenance, good versatility.