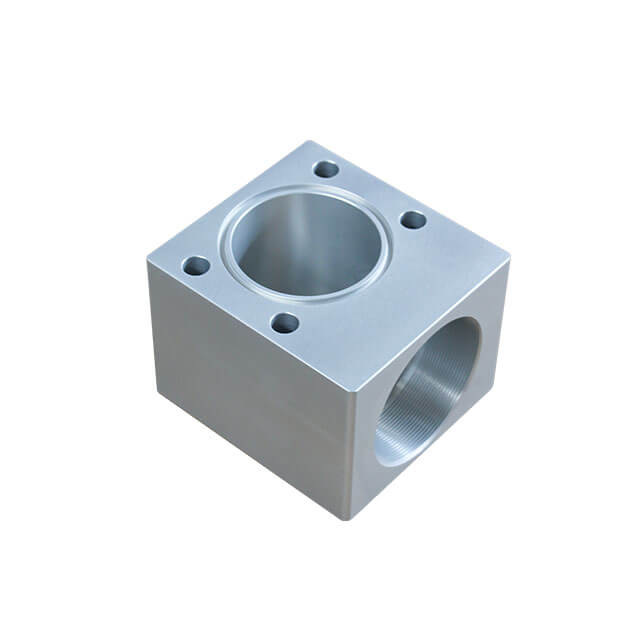

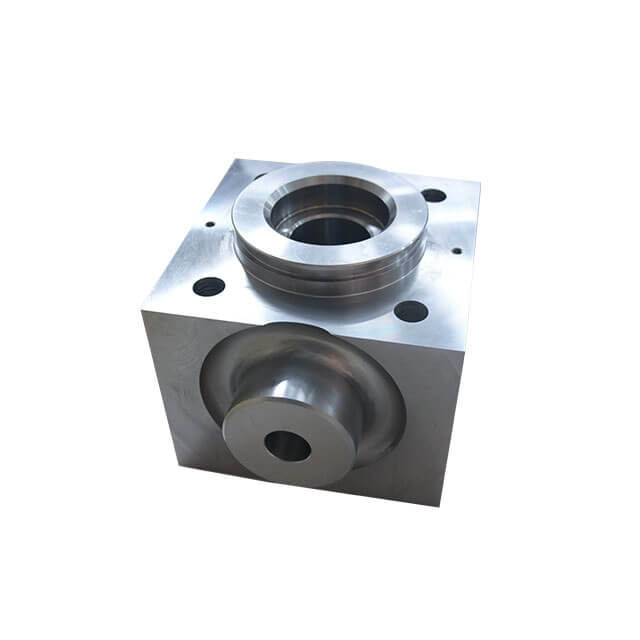

Clean the valve block. Remove all kinds of particle pollutants, corrosives, grease, etc. on the surface of valve block. In order to ensure that the valve block will not rust prematurely in use, it is necessary to carry out antirust treatment. Pickling and phosphating can be used for the internal oil passage of the valve block, and the anti rust treatment process for the external surface mainly includes bluing, cadmium plating, zinc plating, nickel plating and other surface treatment. However, in the process of hydraulic valve block machining, burr often occurs, which is particularly harmful to the hydraulic system. Therefore, there are also relevant grading and evaluation rules for burr quality classification according to surface roughness in the world. Therefore, when the burr of hydraulic valve block appears, in order to ensure the cleanliness of the hydraulic system, the relevant process must be used to remove it.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED