In the field of manufacturing, deburring is a headache problem, the internal cross hole of parts.

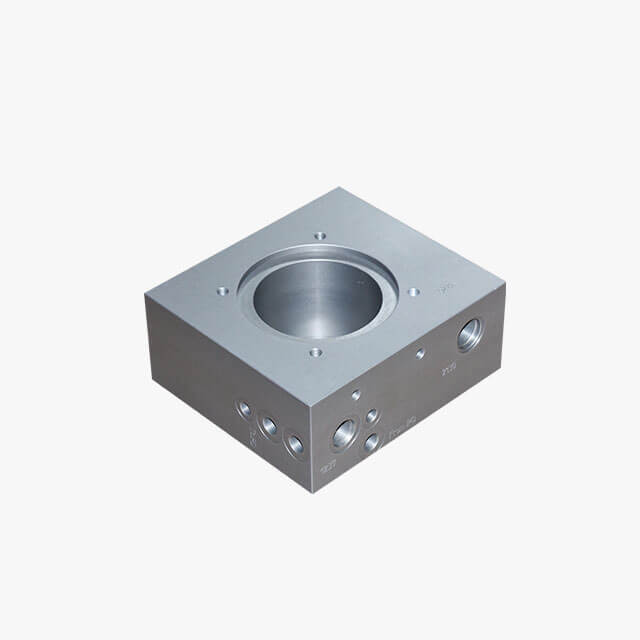

Thermal technology is mainly aimed at deburring the internal cross hole of parts, such as Manifold or oil circuit block in hydraulic industry, ABS valve body in automobile.

After machining, the internal cross holes of parts are too many to be deburred by traditional manual method; The thermal energy process can remove the internal cross hole burrs at one time.

The principle of heat energy technology is to release energy through methane combustion to burn the burr into metal oxide powder, but it will not change the physical and chemical properties of the parts (the metallographic structure of the parts has not changed) like the heat treatment process. Thermal technology is not a fashionable technology, it has obvious advantages and disadvantages.

High efficiency (processing cycle about 1min), internal and external burr removal (methane is gas), wide range of applicable materials (iron, steel, zinc alloy, aluminum alloy, stainless steel, etc.). The disadvantages are that the equipment investment in the early stage is relatively large (low production cost), and it is not suitable for thin-walled parts (deformation).

Hydraulic system manifold block, also known as oil circuit block, valve block and valve island, mainly plays the role of adaptation, transition, conversion, expansion, expansion of hydraulic oil circuit block manufacturer interface and simplification of pipeline. It can make different caliber pipe joints, hydraulic valves and other components match. For complex valve blocks, the material between adjacent holes should have strength, and at the same time, it should be compact without cracks and ash, so as to ensure that there is no leakage and leakage under the possible high oil pressure difference. The commonly used manufacturing material is 35 high-quality medium and low carbon steel, The material selection is based on the fact that the forging has the mechanical strength similar to 45 steel, and is easy to forge and reduce the occurrence of ash inclusion and cracks in the process. It is suitable for the valve block with compact oil circuit structure. Of course, with the progress of China's industrial basic material technology and equipment, 50 steel with lower price and better strength can forge the valve block with good quality, Therefore, the material selection is not fixed on one or several materials. In addition, some special hydraulic oil products used in special occasions by valve block manufacturers have requirements on the corrosion resistance of materials, so they need to use low alloy steel or even stainless steel materials.