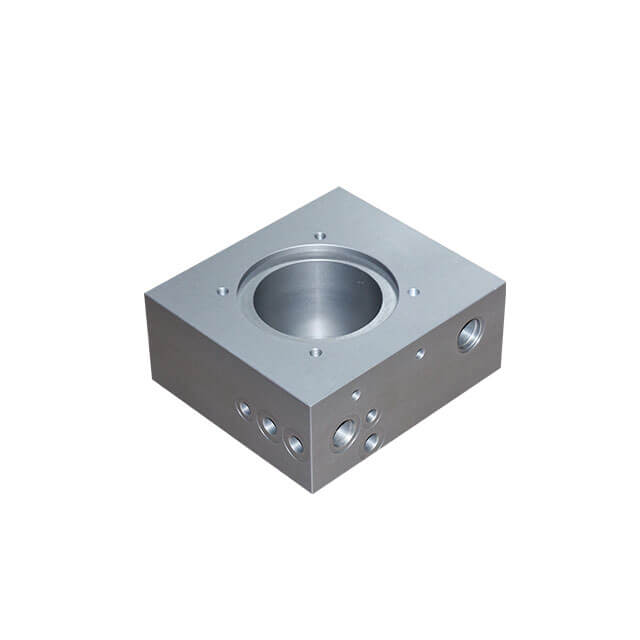

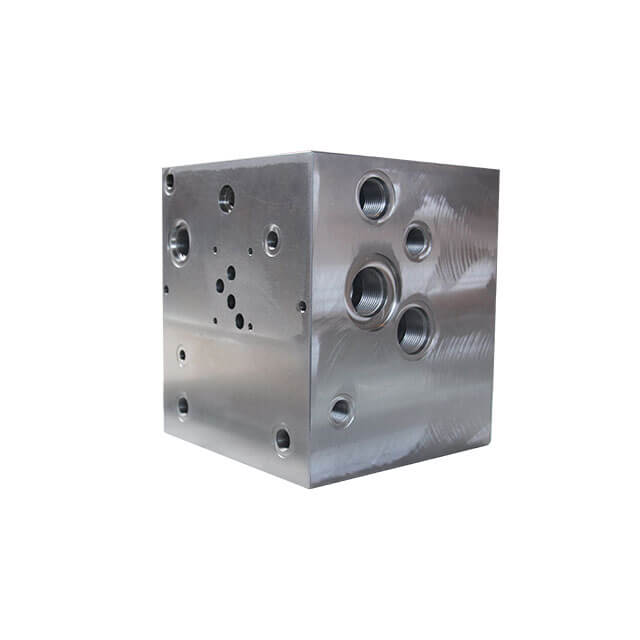

After the design of valve block is completed, the processing technology is as follows: pretreatment. The material for processing valve block shall be compact and free from interlayer, trachoma and other defects. The blank shall be inspected before processing. Cast iron blocks and larger steel blocks should be aged and pretreated before processing. Cutting. Generally, at least 2mm machining allowance shall be reserved for each side. Milling profile. Milling 6 sides of valve block, leaving 0.2-0.4mm rough grinding amount on each side. Rough grinding. Rough grind 6 sides of valve block, leave 0.05-0.08mm fine grinding amount on each side, ensure that the parallelism of each pair of corresponding surfaces is less than 0.03mm, and the perpendicularity of two adjacent surfaces is less than 0.05mm. Draw a line. If possible, it can be directly completed with center drill on CNC drilling machine. Drilling. The surface roughness of each hole is Ra12.5. Fine grinding. Grind 6 surfaces of the valve block to a roughness of ra0.4um. When machining the valve block, the form and position tolerance must be strictly controlled to meet the use requirements. The reference value of form and position tolerance is as follows: the perpendicularity tolerance between the six surfaces of the valve block is 0.05mm; The parallelism tolerance of the opposite surface is 0.03mm; The flatness tolerance of each surface is 0.02mm; The perpendicularity tolerance between the thread and its mating surface is 0.05mm; The tolerance of perpendicularity between all holes and end face is 0.05mm

Deburring and cleaning: in order to ensure the cleanliness of the hydraulic system, the valve block must be deburred. At present, many manufacturers still use brush for manual deburring, but also use methane blasting method for deburring. After deburring, the valve block needs to pass the endoscopic inspection to ensure that the deburring is completed. Clean the valve block. Remove all kinds of particle pollutants, corrosives, grease, etc. on the surface of valve block.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED